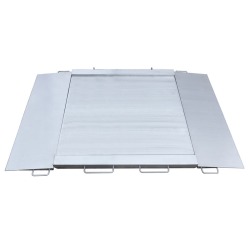

Platforma industriala cu 4 celule WPT/4N 800 H2

Platformele din seria WPT/4N realizate integral din INOX ( inclusiv celulele de sarcina ) sunt utilizate pe scară largă în industria carnii,a peștelui, industria farmaceutica ,industria cosmetica și deasemenea in industria chimică.

Seria WPT / 4N este livrata in configuratia standard cu rampe de acces si incarcare.

Indicatorul este deasemenea realizat din oțel inoxidabil PUE seria C / 31H si este conectat la platforma printr-un cablu.

Rampele de cântare sunt fabricate din oțel inoxidabil OH18N9 cu IP 68. La comandă este posibil să se fabrice platforma într-o versiune superioara de oțel inoxidabil cu proprietati anti-coroziune de grad superior.

Platformele pot fi livrate si în versiunea cu dublu interval de cantarire.

Function adding new mass value to already obtained one. This allows to determine mass content of the mixture, being a composition of number of different consistence components. Totalizing is limited by maximum capacity parameter.

Plus/Minus Control

Percent Weighing function is used for comparision of measured products with mass standard. Mass of a mass standard may be a numeric value taken from a database or it may be determined through a measurement process. Each measured product is compared to mass standard, mass of which is presumed as a model 100% ideal mass. For products weighing less than the mass standard, obtained results are lower than 100%, for products weighing more, the obtained results are greatly exceeded

Function registering the greatest temporary indication occurring in course of the weighing process. It is most often used in medical scales in order to hold the measurement indication.

Function using mass measurement for determination of measured items quantity. Mass of a single item is required for this process. It may be either estimated through weighment or taken from a database. For items counting the following algorithm is used: all items mass / single item mass = quantity. Function operation is supperted by a mechanism of Automatic Correction of Accuracy. This allows to update single item mass in course of the process. To a certain extend Automatic Correction of Accuracy eliminates error which may be a result of different mass values of seemingly alike single elements. For industry solutions items counting may be simultaneously carried out with checkweighing and dosing thus industry solutions feature audio signalling base informing that specified number of items has been weighed. It is possible to apply weighing systems using few platfroms of different MAX capacities and different accuracies.

Function allowing to perform the measurement in Newton unit, it may be used for processes aiming to determine force resulting in the sample damage.

Process of mass determination for a product which may unwillingly reposition within the weighing pan. Mass determination in such cases requires much longer period of time when compared to typical weighing process. It is the user who defines period of time needed for control of measured product mass. The user can thus optimaze the function depending on the measured product characteristics.

| Capacitatea maxima [Max] | 800 kg |

| Readability | 500 g |

| Tare range | -800 kg |

| Pan Size | 1100×1200 mm |

| Working temperature | -10° - +40 °C |

| Atmospheric humidity | 10÷85% RH no condensation |

| IP rating | IP 68 construction, IP 68 (1h max)/69 indicator |

| Power supply | 100 ÷ 240 V AC 50 ÷ 60 Hz / 12 V DC + battery |

| Display | LCD (backlight) |

| Interface | RS 232 |

Totalizing

Totalizing Plus/Minus Control

Plus/Minus Control Percent weighing

Percent weighing Peak Hold

Peak Hold Parts counting

Parts counting Newton unit measurement

Newton unit measurement Internal battery

Internal battery Animal weighing

Animal weighing